Comparison between technical ceramics and traditional ceramics

1. Comparison between technical ceramics and traditional

ceramics.

Technical ceramics, also known as advanced ceramics, are a specialized

type of ceramic materials that are engineered to have specific properties

and characteristics that are not found in traditional ceramics. These

properties typically include high strength, hardness, toughness, wear

resistance, chemical resistance, and thermal stability. Technical ceramics

are used in a wide range of high-performance applications such as

aerospace, electronics, automotive, medical implants, and industrial

machinery.

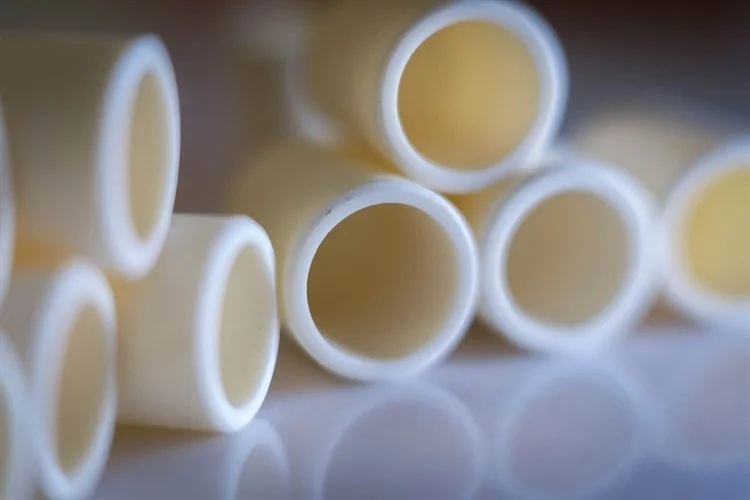

On the other hand, traditional ceramics are the more common types of

ceramics that have been used for centuries. They are typically made from

raw materials such as clay and are fired at high temperatures to create a

hard and durable material. Traditional ceramics are used in a wide range of

applications such as pottery, building materials, and decorative items.

Unlike technical ceramics, traditional ceramics do not have specialized

properties and are not engineered for specific applications.

2. What is technical ceramics?

Technical ceramics, advanced ceramics or engineering ceramics, refer to a

range of inorganic materials that possess exceptional physical and

chemical properties. These ceramics are engineered to display excellent

mechanical strength, high-temperature resistance, wear resistance, and

electrical insulation, among other properties. Technical ceramics are

utilized in a vast array of applications and industries, including aerospace,

automotive, energy and power, defense, electronics, medical devices, and

industrial manufacturing, among others. Some common examples of

technical ceramics include alumina, zirconia, silicon carbide, and boron

nitride. One of the main advantages of technical ceramics is their superior

mechanical properties, including high strength, hardness, and fracture

toughness, which allows them to withstand extreme conditions in high-

stress applications.

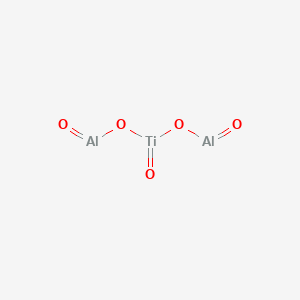

For instance, alumina (Al2O3) is widely used in mechanical and structural

components because of its high strength, stiffness, and wear resistance,

making it ideal for applications such as cutting tools, bearings, and pumps.

Another significant advantage of technical ceramics is their high-

temperature resistance, which enables them to withstand extreme heat

during manufacturing, processing, and use. For example, silicon carbide is

employed in high-temperature applications, such as furnace linings, kiln

components, and turbocharger parts, because of its excellent thermal

conductivity, low thermal expansion, and high thermal shock resistance.

Moreover, technical ceramics possess remarkable electrical and thermal

insulating properties that make them suitable for electronic and electrical

applications. These ceramics are used in electrical and electronic

components such as capacitors, insulators, and spark plugs because of

their high dielectric strength, low dielectric loss, and excellent thermal

stability. In conclusion, technical ceramics are versatile materials that offer

exceptional properties that make them ideal for a range of applications.

Their superior mechanical properties, high-temperature resistance, and

excellent electrical insulation make them invaluable in industries such as

aerospace, automotive, energy and power, defense, medical devices, and

industrial manufacturing. These materials are critical to many modern

technologies, and their continued development and innovation hold the key

to solving some of the world’s most pressing challenges.