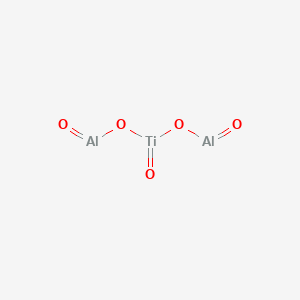

Aluminum Titanate (Al2TiO5)

The special feature of aluminum titanate (Al 2 TiO 5 ) is its excellent thermal

shock resistance. Components made of this material can withstand even the

most abrupt temperature changes of several hundred degrees without damage,

although they have low strength.

The good thermal shock resistance is a result of the very low thermal

expansion and a certain amount of porosity in the microstructure. This

ceramic material’s poor wettability with molten metals also makes it ideal

for use in foundry technology and metallurgical melting .

Properties of Aluminum Titanate (Al2TiO5)

Excellent thermal shock resistance

Max. operating temperature: 900 °C (in some cases could reach 1100°C

but only for a short period of time)

Very low thermal expansion (<1×10 -6 K -1 between 20 and 600°C)

High thermal insulation (1.5 W/mK)

Low Young’s modulus (17 to 20 GPa)

Good chemical resistance

Poor wettability with molten metals

Longer service life, can be exposed to molten metal without pre-heating

Energy-efficient process, increased process reliability, reduced freeze-

offs and improved yield levels

Prevents metal adhesion, simplifies cleaning and increased machine

availability

Increased service life, does not contaminate the melt hence enhances

product quality plant efficiency

Low Thermal Conductivity

Aluminum titanate has outstanding properties that make it ideally suited for

applications involving molten aluminum, including complete resistance to

wetting by aluminum alloys, total gas impermeability, and a very low thermal

expansion coefficient. This material offers a longer service life and higher

reliability when compared to cast iron, calcium silicate or fused silica

components. All riser/stalk tubes are 100% leak-down tested.

Feeders / Risers / Stalk for low pressure die casting Dosing tubes

Dosing tubes

Ceramic containers

Sprue bushings, Cups and Connectors

Casting spouts, Flow rods, Retainer rings

Nozzles, Crucibles

Tap hole plugs and rings

Customised special components

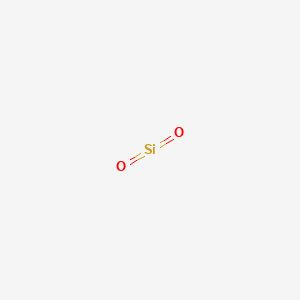

Fused Silica

Fused Silica

The fused silica of Techceramic-M has low coefficient of thermal

expansion, thermal shock resistance, good chemical resistance.

It has good dimensional stability and excellent refractory capabilities

needed for products like launders, stoppers, baffle plates.

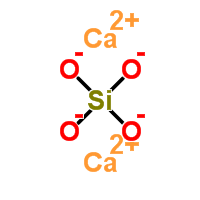

Calcium silicate

Techceramic-M’s calcium silicate has high-insulating properties with

density lower than 1,5 gr/cm3 and is non-wetting by aluminum alloys.

It is produced in cylindrical, conical configurations, which are

symmetric depending on client’s wish.

It is excellent for producing insulation bushings, intermediate tubes,

working in sprue systems for die casting aluminum alloys.

Calcium silicate

Techceramic-M’s calcium silicate has high-insulating properties with

density lower than 1,5 gr/cm3 and is non-wetting by aluminum alloys.

It is produced in cylindrical, conical configurations, which are

symmetric depending on client’s wish.

It is excellent for producing insulation bushings, intermediate tubes,

working in sprue systems for die casting aluminum alloys.

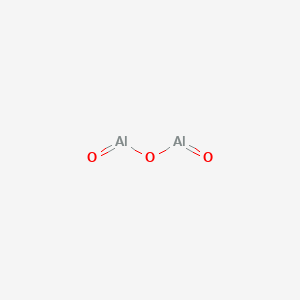

Alumina

Alumina is one of the most widely specified, general-purpose technical ceramics.

All aluminas are very hard and wear resistant, with high compressive strength even

against extreme temperatures and corrosive environments. Aluminas are also excellent

electrical insulators and are gas tight.

Commercially available grades range from 92% up to 99.95% with the higher purity

generating higher hardness. It is possible to machine alumina using diamond grinding

techniques. Polishing is also possible, with the degree attainable affected by alumina

grain size and production technique.

Properties of Alumina/Aluminum Oxide (Al2O3)

Very good electrical insulation

Construction material

Moderate to extremely high mechanical strength

Very high compressive strength

High hardness

Moderate thermal conductivity

High corrosion and wear resistance

Good gliding properties

Operating temperature without mechanical load 1,000 to 1,500°C.

Bioinert and food compatible

Acids resistance

Advantages of alumina ceramics

High mechanical strength;

High resistivity;

Good electrical insulation performance;

High hardness;

Resistant to acids;

The density of alumina ceramics is 3.6g/cm3, which is only half of the density of the

steel, which can greatly reduce the equipment load;

High melting point, anti-corrosion, melting point 2050℃, can resist the erosion of molten

metals such as Be, Sr, Ni, Al, V, Ta, Mn, Fe, Co. It also has high resistance to erosion of

NaOH, glass and slag;

Alumina ceramics have excellent chemical stability, and do not chemically react with

many complex sulfides, such as phosphides, arsenides, chlorides, nitrides, bromides,

iodides, oxides, sulfuric acid, hydrochloric acid, nitric acid, and hydrofluoric acid.

Typical alumina applications include:

Seal rings

Blood seals and valve

Ballistic armour

Threadguides

Wear components

Zirconia (Zro2)

Zirconia (Zro2) ceramic offers a combination of high hardness, wear and corrosion

resistance, while exhibiting one of the highest fracture toughness values among all

ceramic materials.

General Properties

Use temperatures up to 1500°C

Sintered to full density for a pore free structure

No compromise between bending strength, hardness and fracture toughness

Remarkably high fracture toughness and impact resistance while maintaining

above average values for bending strength and hardness

Toughening by crack deflection provided by a unique microstructure in a partially

stabilised zirconia matrix

Applications of Zirconia

Zirconia is used in applications typically in the metal forming industry

As the material, zirconia is wear resistant and inert and can therefore be utilised in areas

where traditional metallic systems would not be able to function. In sub-sea systems

where metallic systems would corrode, zirconia excels.

Zirconia is used as an oxygen sensor due to the free charge carriers within the structure.

Specific grades of zirconia can become electrically conducting at high temperatures due

to the energy imputed into the material which liberates the charge carriers to carry the

current.

Zirconia has great wear resistance, which combined with the high fracture toughness

properties makes it an ideal material for pumps.