Products

Foundry products

Techceramic M manufactures several ceramic materials specially developed for use in foundries.One of these ceramic materials is Aluminium Titanate. Ultra-clean synthetic raw materials are combined to form a micro porous material by special reaction sintering. This material is characterized by:

- Superb resistance to corrosion & erosion

- High insulating values

- Low heat conduction

- Electrically stable

- High temperature and thermal resistant

- Non-wetting by non-ferrous metals

- Outstanding lifespan

- Excellent price-to-performance ratio

- Exceptional thermal shock resistance

- No thermal expansion

- Secures economic process control

- Guarantees constant cleanness of melt

Insulation products

Techceramic M Ltd. specialize in the production of Wollastonite and Fused Silica parts for molten aluminium contact. Due to the materials excellent properties, components based on both materials are perfect for use in casting operations. The advantages of this material are characterized by:

- Good insulation

- Non-wetting to molten Aluminium alloys

- Good thermal

- Erosion resistance

- Excellent price-to-performance relation

Balistic ceramic

Techceramic specializes in the development and production of ballistic ceramics, products that are an essential part of the protective armor, which destroys the front of the bullet, extinguishes its kinetic energy, and prevent penetration and further striking ability.

Cast-house products

For several years Techceramic M Ltd. has developed technology for the production vacuum-formed products. Made from ceramic fiber, refractory components and a small percentage of organic or non-organic binder, the insulating properties, high operation temperature and cohesive strength are perfect for foundry applications. The versatility of the vacuum-formed process facilitates the manufacture of simple forms, such as cones and tubes, while also geometrically complex shapes. The basic process is developed to correspond to customer requirements. Custom-made parts are available on request.

Furnace products

Made from high purity refractory materials, these insulating fire elements, special refractory bricks, tubes for heaters and kiln furniture, contain carefully graded organic filler which is burned out during manufacturing in order to give a uniform, controlled structure. The materials advantages include high insulation value and low heating costs. Custom-made parts are available on request.

Structural ceramics

For highly corrosive and or abrasive fluids, high-grade alumina is typically used for its superb strength and wear resistance in structural engineering ceramic components. Its range of applications includes;

For highly corrosive and or abrasive fluids, high-grade alumina is typically used for its superb strength and wear resistance in structural engineering ceramic components. Its range of applications includes;

- Valve discs

- Pistons

- Washers

- Valves of pumps

- Extrusion cores

- Cyclone separators cones

- Inert gas welding nozzles

- Wire handling pulleys and guides

- Fluid seals

Ceramics for the electrical and electronics industries are made from alumina, cordierite and related materials. These materials possess stable electrical characteristics over a wide frequency and voltage range. Typical applications include heater carriers, integrated circuit substrates and high voltage insulators. Equipped with Cold Isostatic Pressing machine, using Dry Pressing, Injection Molding Casting and Mashing methods, Techceramic M is capable of manufacturing components from small to very large dimensions with precise tolerances.

Textile ceramics

Ceramics are used in the textile industry for filament (thread) guides. Corundum filament guides are fabricated from sintered aluminium oxide to deliver superior hardness and wear resistance. They find application in abrasive technical ceramic fiber production and mixed fiber yarns. After special processing they are even used for metallic wire manufacturing. Custom-made parts are available on request.

Wear resistant ceramics

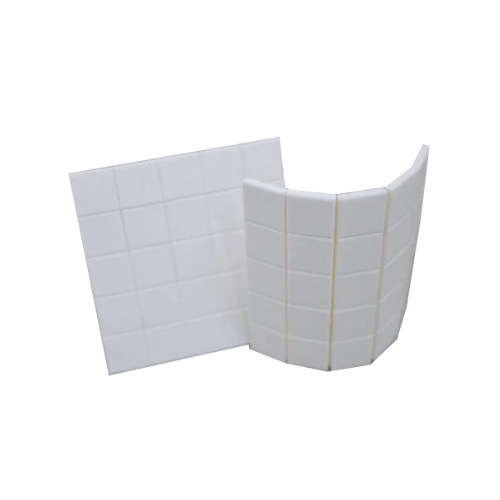

Ceramic lining Techceramic-Protect is a complete wear-resistant system for heavy-duty belt conveyors, which including the following elements:

– High wear-resistant ceramic material Al2O3, specially shaped tiles, combined in an arrangement suitable for the application;

– Specially shaped cylinders and elbows;

– Specially developed gluе;

– Surface preparation of the components;

– Installation works according to proven operating procedures;

Only by fulfilling all the requirements of the system, the application of belt conveyors is successful.

Our recommendation: Extend service life, improve performance and reduce the stops by using ceramic tiles on Techceramic-Protect for your belt conveyors.