Aluminum Titanate

Technical ceramics are a diverse group of materials known for their exceptional mechanical,

thermal, electrical, and chemical properties. Among these advanced ceramics, aluminum

titanate stands out as a remarkable material with unique properties that make it suitable for

various high-temperature applications. In this article, we will delve into the manufacturing

process of technical ceramics, with a particular focus on aluminum titanate.

Understanding Technical Ceramics

Technical ceramics, also known as engineering ceramics or advanced ceramics, are a class

of materials that are distinct from traditional ceramics like pottery or bricks. They are

engineered for specific high-performance applications that demand exceptional properties,

such as high melting points, extreme hardness, excellent thermal and electrical insulation,

and resistance to wear and corrosion.

Key characteristics of technical ceramics include:

- High Temperature Resistance: They can withstand extreme temperatures, making

them ideal for applications in aerospace, automotive, and energy industries. - Superior Mechanical Strength: Technical ceramics exhibit exceptional mechanical

properties, including high hardness, strength, and fracture toughness. - Electrical Insulation: They are excellent electrical insulators, making them suitable for

electrical components and insulators. - Chemical Inertness: They are highly resistant to chemical corrosion, which makes

them ideal for use in aggressive environments. - Precision Manufacturing: Technical ceramics can be precisely machined into

complex shapes, which is crucial for various applications.

The Manufacturing Process for Technical Ceramics

The manufacturing process for technical ceramics is a highly specialized and controlled

procedure that involves several stages:

1. Raw Material Selection:

The first step is to carefully select and source high-purity raw materials. These

typically include oxides of elements like aluminum, silicon, zirconium, and titanium.

2. Powder Preparation:

The selected raw materials are ground into fine powders to ensure uniform particle

size and distribution. This is crucial for achieving consistent properties in the final product.

- Mixing:

The powders are thoroughly mixed with binders and additives to create a

homogeneous ceramic slurry. This mixture is then shaped into the desired form

through processes like extrusion, pressing, or injection molding. - Green Machining:

The formed green body, which is still in a fragile state, is precision-machined to

achieve the desired shape and dimensions. This step is essential for creating

intricate components. - Drying:

The green body is carefully dried to remove moisture and solvents, ensuring

structural integrity. - Sintering:

Sintering is the key step in the manufacturing process. The green body is heated to

high temperatures (often above 1,000°C) in a controlled atmosphere. During

sintering, the ceramic particles bond together, resulting in a dense, high-strength

ceramic material.

Aluminum Titanate: A Specialized Technical Ceramic

Aluminum titanate (Al2TiO5) is a specialized technical ceramic that has garnered attention

for its unique properties, particularly in high-temperature applications. It exhibits a low

coefficient of thermal expansion (CTE) over a broad temperature range, making it suitable

for applications where thermal shock resistance is critical.

The manufacturing process for aluminum titanate includes:

1. Raw Material Preparation:

High-purity alumina (Al2O3) and titania (TiO2) powders are carefully mixed in precise

proportions to form a homogeneous blend.

2. Shaping:

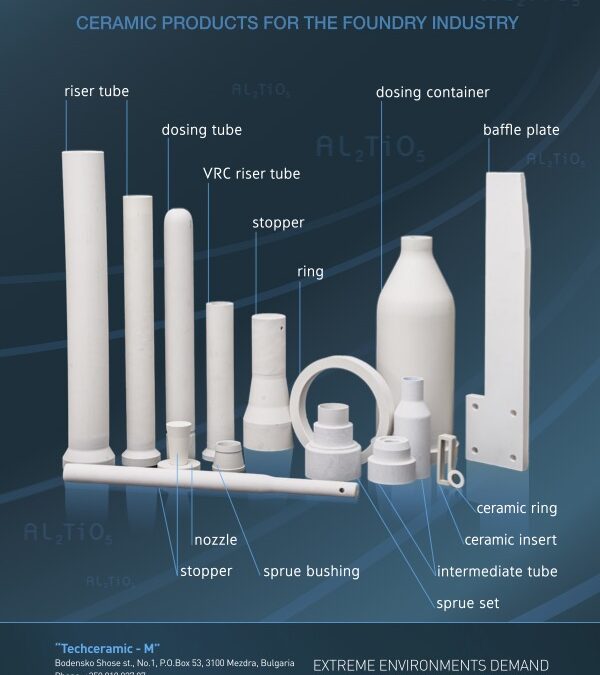

The mixed powders are shaped into the desired form, such as plates, crucibles, or

riser tubes, dosing tubes and sprue system, using pressing or extrusion.

3. Sintering:

The shaped green bodies are subjected to high-temperature sintering in a controlled

atmosphere to form fully dense aluminum titanate ceramic components.

Technical ceramics, including aluminum titanate, play a vital role in numerous high-

temperature and demanding applications across various industries. The manufacturing

process for these advanced materials involves a series of well-defined steps, from raw

material selection to precision machining and sintering. Understanding and controlling these

processes are essential to produce technical ceramics with exceptional properties, ensuring

they meet the stringent requirements of modern technology and industry.