Alumina Green Tape in Thick Film Printing: Versatile Electronic Component Manufacturing

Thick film printing stands as a pivotal manufacturing technology in the electronics industry, facilitating the creation of intricate and functional electronic components. This process involves the deposition of a thick layer of specialized ink or paste onto a substrate, enabling the formation of various electronic elements. One specific application of this technique is casting alumina green tape, which yields versatile and high-performance components.

What is Alumina Green Tape?

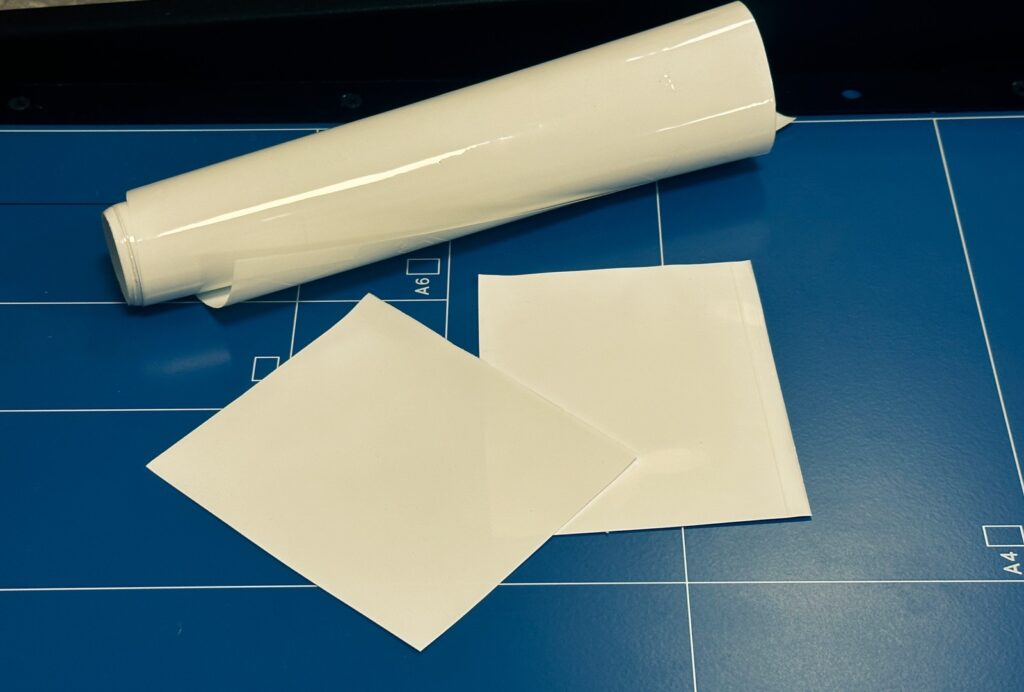

Alumina green tape, often referred to as ceramic green tape, constitutes a flexible substrate composed of alumina powder blended with organic binders and solvents. This material boasts several advantages, including exceptional electrical insulation, resistance to high temperatures, and robust mechanical stability. Its flexibility and moldability make it an ideal choice for crafting complex shapes and three-dimensional structures. When employed in thick film printing, alumina green tape facilitates precise and controlled deposition, resulting in components with unique electrical and mechanical properties.

The Process of Casting Alumina Green Tape

The process of casting alumina green tape involves several key steps. First, alumina powder is combined with organic binders and solvents to create a homogeneous slurry. This slurry is subsequently cast onto a flexible substrate, such as plastic or ceramic sheets, using a doctor blade or roller. The thickness of the cast layer can be accurately controlled by adjusting the blade height or roller pressure. Following casting, the green tape is dried to remove solvents, resulting in a flexible, green-colored sheet.

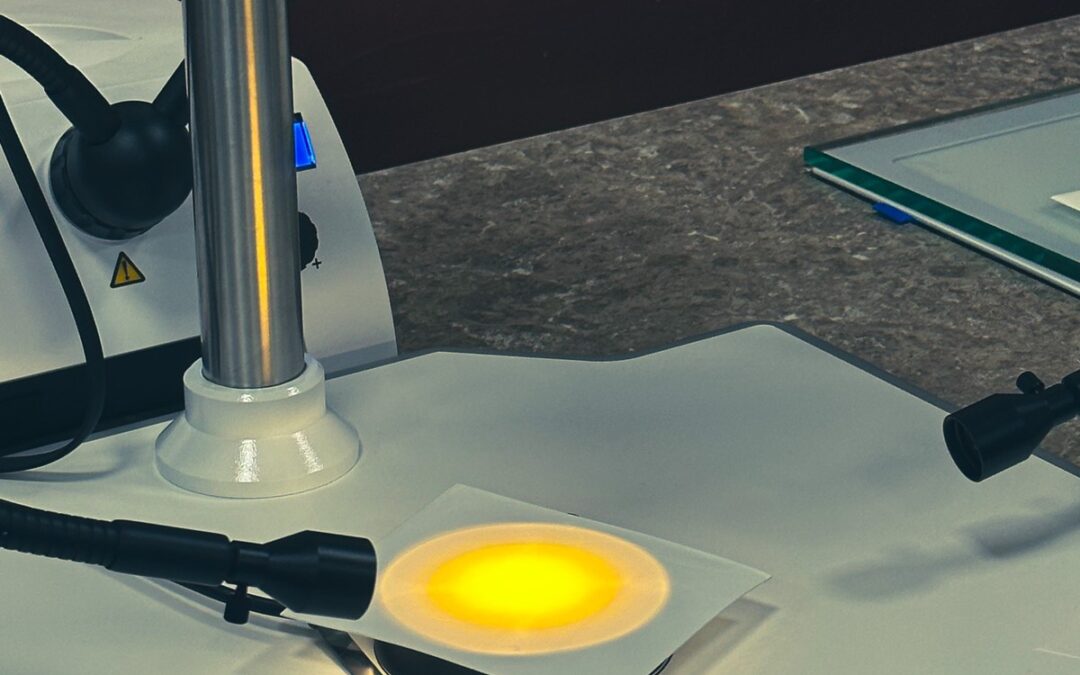

Thick Film Printing Techniques

With the prepared green tape, thick film printing techniques come into play for creating circuitry and other electronic components on its surface. Screen printing is a common method, where a stencil with the desired pattern is positioned over the green tape. Thick film paste, containing conductive or insulating materials, is then pushed through using a squeegee or doctor blade. This paste adheres to the green tape, forming the intended circuit or component. Complex multilayer structures can be achieved by stacking and printing multiple layers of green tape.

The Firing Process

Following the printing process, the green tape undergoes a firing or sintering process. This critical step removes organic binders, fuses alumina particles together, and transforms the green tape into a solid, highly dense ceramic material. The firing temperature and duration are meticulously controlled to ensure complete binder removal and adequate particle sintering. The resulting components exhibit excellent electrical conductivity or insulation, depending on the composition of the printed layers, along with high mechanical strength and stability.

Applications in the Electronics Industry

Components manufactured from cast alumina green tape find extensive applications in the electronics industry. They are frequently used in the fabrication of integrated circuit substrates, multilayer ceramic capacitors, high-frequency modules, and various other electronic devices. The capability to create intricate three-dimensional structures, combined with alumina’s excellent electrical properties, positions cast green tape as a compelling choice for miniature and high-performance electronic components.

In Conclusion

Thick film printing techniques applied to casting alumina green tape offer a versatile and effective approach to producing intricate electronic components. By depositing thick layers of alumina paste onto green tape and subjecting it to controlled firing, durable and high-performance components can be achieved. From integrated circuit substrates to multilayer ceramic capacitors, cast alumina green tape plays a vital role in an array of electronic devices. This underscores the significance and adaptability of thick film printing in modern electronics manufacturing.